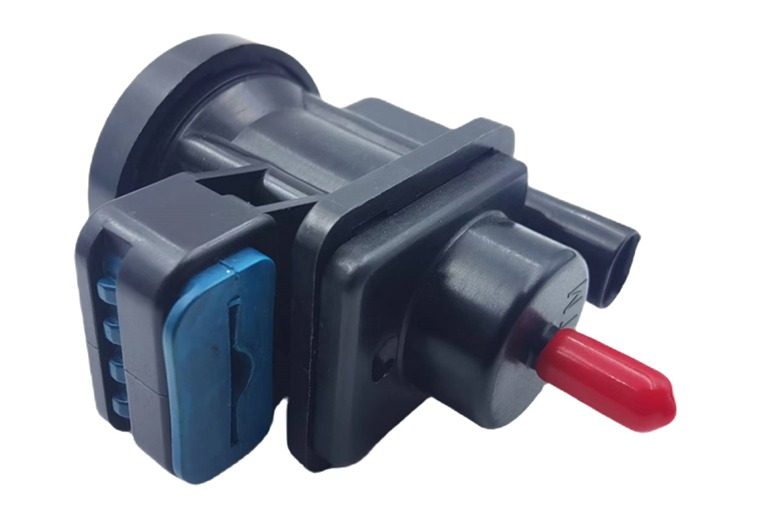

Automotive Electronic Water Pumps have become increasingly important components in modern vehicle cooling and heating systems. Unlike traditional mechanical pumps, these electronic water pumps offer more precise control over coolant flow, enabling improvements in engine efficiency and emission reduction.

The primary role of the Automotive Electronic Water Pump is to circulate coolant through the engine, radiator, and heating system. By doing so, it maintains engine temperature within a specific range, which is critical for good combustion and emission control. Precise temperature regulation reduces fuel consumption and lowers harmful emissions. The electronic control of these pumps allows them to adjust flow rates dynamically, responding to engine load and external conditions.

The integration of the Automotive Electronic Water Pump with the vehicle’s control systems also supports advanced engine management strategies. For example, during cold starts, the pump can reduce flow to allow the engine to warm up faster, which helps the Automobile Heating Control Valve deliver heat to the cabin more quickly. Conversely, under heavy engine loads or high temperatures, the pump increases coolant circulation to prevent overheating.

Traditional mechanical water pumps operate at a fixed speed driven by the engine’s belt system, which means they can pump more coolant than necessary at low engine loads, wasting energy. In contrast, the Automotive Electronic Water Pump can vary its speed independently, providing coolant only as needed. This flexibility reduces the mechanical load on the engine, improving fuel efficiency. Over time, such efficiency gains contribute to lower carbon emissions and better overall vehicle performance.

By optimizing coolant flow, the Automotive Electronic Water Pump works in tandem with the Automobile Heating Control Valve to maintain a stable and comfortable cabin environment. The heating control valve regulates hot coolant delivery to the heater core, while the water pump ensures that the coolant flow is steady and sufficient.

Durability and reliability are also important aspects of the Automotive Electronic Water Pump. Advanced materials and sealing technologies have improved pump longevity, even under harsh operating conditions. The pump’s electronic components are designed to withstand temperature variations and vibrations typical in automotive environments. Such durability ensures consistent engine cooling and heating system performance throughout the vehicle’s service life.

Another benefit of the Automotive Electronic Water Pump is its contribution to reducing engine wear. By maintaining consistent engine temperatures, the pump prevents thermal stresses that can damage engine components. Proper temperature control also supports emission control systems like catalytic converters, which operate more efficiently within specific temperature ranges.

Environmental regulations and consumer demand for fuel-efficient vehicles continue to drive innovation in cooling system components like the Automotive Electronic Water Pump and the Automobile Heating Control Valve. Automakers increasingly adopt these technologies to meet stringent emission standards without compromising driver comfort or vehicle performance.

The Automotive Electronic Water Pump plays a vital role in improving engine efficiency and reducing emissions. Its ability to dynamically adjust coolant flow, in coordination with the Automobile Heating Control Valve, ensures effective engine temperature management and comfortable cabin heating. Advances in materials and control technologies continue to enhance pump reliability and performance, supporting the evolving needs of modern vehicles.

The ongoing development of the Automotive Electronic Water Pump alongside the Automobile Heating Control Valve reflects the automotive industry’s commitment to balancing environmental responsibility with user comfort. These components form a key part of vehicle systems designed to meet current and future challenges in efficiency and emission reduction.

English

English русский

русский Español

Español

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>